Air compressors are an essential component in modern industry, serving a wide range of applications across various sectors. They are devices that convert power into potential energy stored in compressed air. This compressed air can be used for powering tools and equipment, as well as for pneumatic control systems. The history of air compressors dates back to ancient times when people used simple hand-operated bellows to generate compressed air. Read More…

At Delta Industries, we specialize in delivering comprehensive compressed air solutions that power a wide range of industrial applications. Our focus is on providing high-performance air compressors, along with the support systems and technical expertise our customers need to keep operations running smoothly and efficiently. We offer everything from rotary screw and reciprocating compressors to...

At U.S. Air Compressor, we specialize in delivering high-performance compressed air solutions that keep operations running smoothly across a wide range of industries. As a team with decades of experience in the field, we understand the critical role air systems play in productivity, and we take pride in providing reliable, efficient, and expertly engineered equipment.

At Quincy Compressor, we manufacture rugged, reliable air compressors and air system solutions built to perform in the most demanding industrial environments. For over a century, we’ve been at the forefront of compressed air technology, designing and engineering equipment that stands up to the toughest jobs while delivering maximum efficiency and productivity.

At Campbell Hausfeld, we’ve dedicated more than 180 years to helping professionals and DIYers alike get jobs done with confidence. As a trusted name in compressed air solutions, we manufacture and support a comprehensive range of air compressors designed for both residential and industrial use.

More Air Compressor Manufacturers

What is the Brief History of Air Compressors?

Answer: Air compressors have a rich and dynamic history, closely intertwined with humanity’s ongoing quest to harness and control energy for industrial and practical applications. Tracing back centuries, the evolution of air compression technology showcases major innovations that have shaped modern industry.

Early forms of air compression can be seen in the 17th century when German physicist Otto von Guericke pioneered vacuum pump experiments that laid the foundation for manipulating air pressure. By the late 18th century, blacksmiths were using hand-operated bellows—rudimentary air compressors—to intensify the heat of their forges, revolutionizing metalwork and setting the stage for more advanced tools.

The Industrial Revolution marked the dawn of commercial air compression. In 1829, George Medhurst patented a motorized air compressor for railway propulsion—an innovation ahead of its time. The 1860s witnessed transformative advancements: French engineer Benoît Fourneyron developed piston compressors powered by steam engines, which quickly found adoption in mining and factory settings. Compressed air began to replace steam, offering a safer and more flexible alternative to power drills, ventilation systems, and industrial machinery.

The 20th century saw electricity accelerate the development of air compressor technology. Rotary screw and centrifugal compressors—both offering greater efficiency and higher output—emerged around the early 1900s. These innovations underpinned the growth of mass production lines, such as those made famous by Ford Motor Company. World War II further drove innovation; portable air compressors powered pneumatic tools essential for military construction and infrastructure.

The post-war era of the 1950s ushered in compact, oil-free air compressors, catering to the stringent requirements of medical, dental, and food processing applications. Today, air compressors are integral to automotive repair shops, manufacturing plants, HVAC systems, and countless other settings, with industry leaders like Ingersoll Rand continuing to build on the legacy of early piston-driven machines.

From humble bellows to high-tech, automated units, air compressors have evolved into indispensable assets across virtually every sector. Their development mirrors advances in industrial automation, energy management, and safety—making them vital tools for both commercial and personal use.

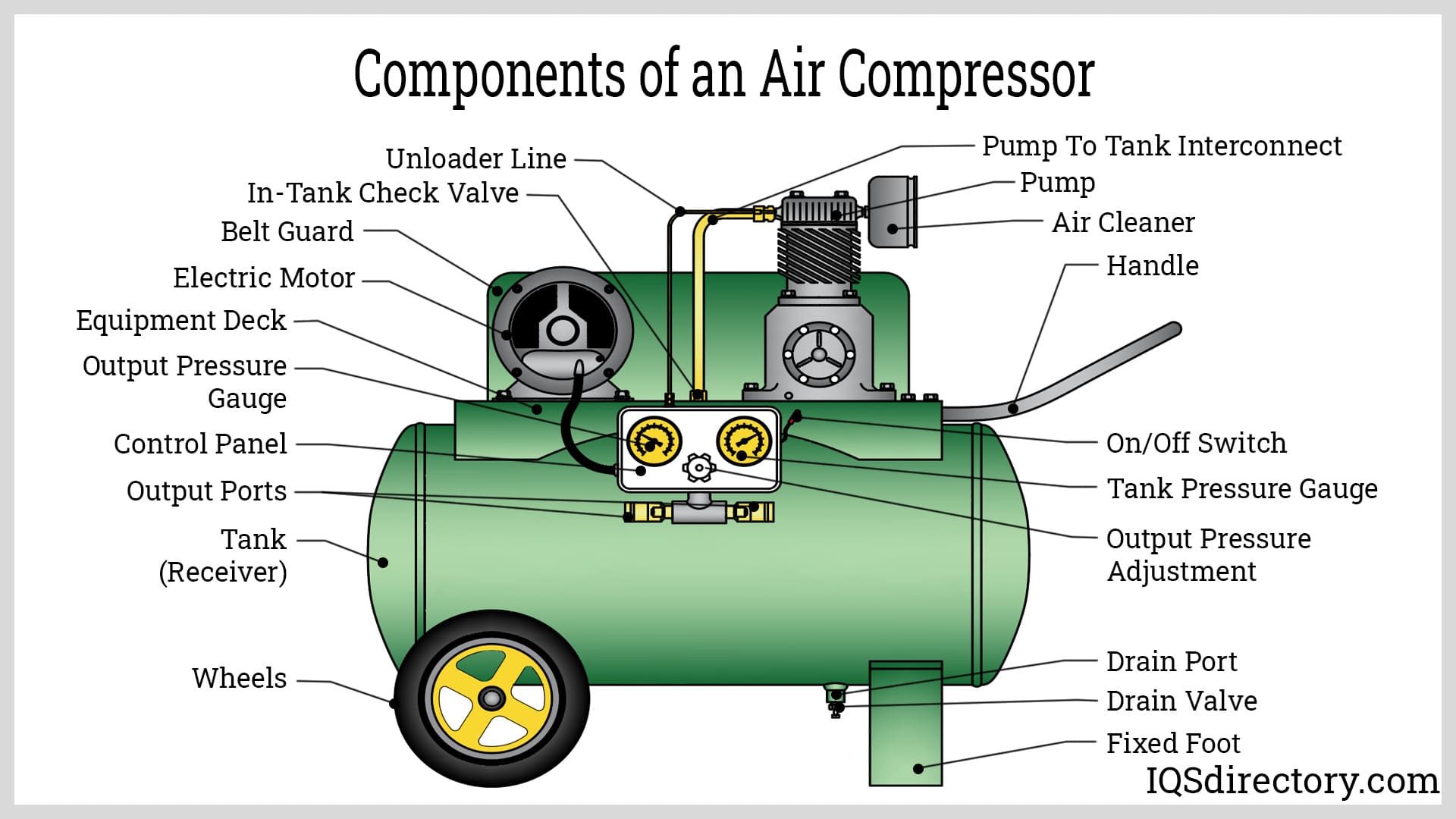

Components of Air Compressors

Air compressors function by compressing atmospheric air, increasing its pressure, and storing it for later use across a range of applications. Understanding the main components of an air compressor is essential for buyers and operators aiming to select the best unit for their specific needs. Below, we break down the essential air compressor parts and their functions, highlighting the importance of each in delivering reliable compressed air.

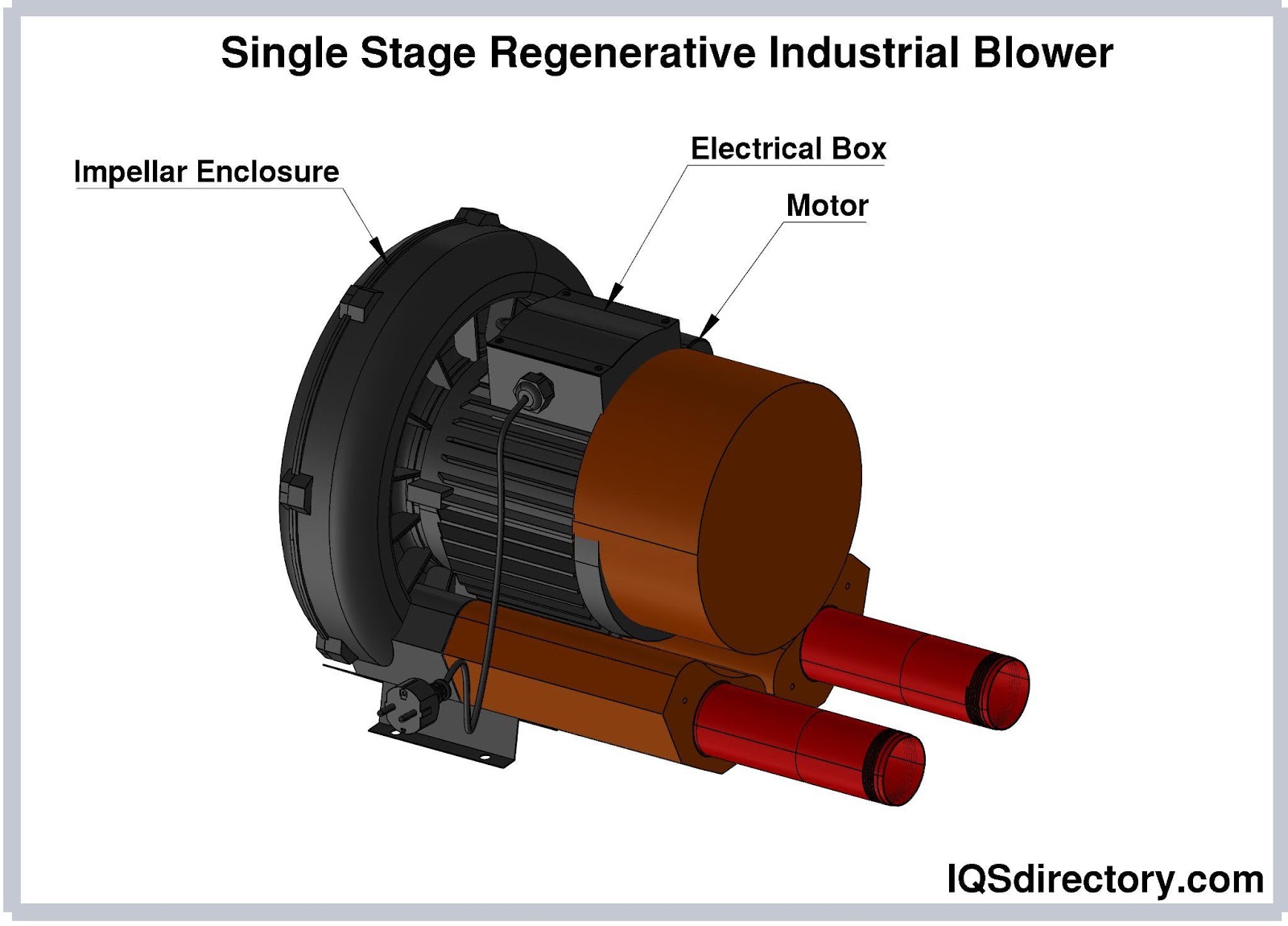

Motor: The motor is the power-generating heart of the air compressor. Motors may be electric, gasoline, or diesel-powered, with electric motors being most common in stationary or indoor settings due to their efficiency and lower emissions. Gasoline or diesel motors are typically found in portable or remote-use compressors where electricity is unavailable.

Pump: The compressor pump is responsible for compressing the air and increasing its pressure. There are several types of compressor pumps: reciprocating (piston), rotary screw, and centrifugal. Each pump design offers distinct advantages in terms of airflow, pressure, efficiency, and suitability for intermittent or continuous-duty cycles. For instance, reciprocating pumps are ideal for light-duty or intermittent use, while rotary screw and centrifugal pumps excel in heavy-duty, industrial environments.

Air Tank (Receiver): The air tank acts as a pressurized reservoir, storing compressed air until it is needed. Air receiver tanks vary widely in size and capacity depending on the compressor’s intended application—from small portable models for tire inflation to massive stationary tanks for factory-scale pneumatic systems. Safety features, such as pressure relief valves and automatic shutoff controls, are crucial to prevent over-pressurization.

Gauges: Air compressors are equipped with pressure gauges to monitor and maintain optimal operational safety. Typically, one gauge displays the pressure inside the tank (tank pressure), while another shows the pressure at the regulator or outlet (regulated pressure) to ensure safe and effective tool operation.

Valves: Several types of valves work together to regulate airflow within the compressor system:

- Inlet Valve: Controls the intake of atmospheric air into the pump.

- Discharge Valve: Releases compressed air from the pump into the storage tank.

- Check Valve: Prevents backflow of compressed air from the tank back into the pump.

- Safety Valve: Automatically vents excess pressure to prevent dangerous over-pressurization.

Other important air compressor accessories may include air filters (to remove contaminants), dryers (to reduce moisture), regulators (to fine-tune outlet pressure), and drain valves (to expel collected water and maintain system integrity).

Every component in an air compressor is essential to its operation. By working together, these parts transform mechanical energy into stored potential energy, making compressed air accessible, manageable, and safe for a wide array of industrial, commercial, and residential applications.

Types of Air Compressors

When researching which air compressor to buy, understanding the different types of air compressors is crucial. Each compressor type is engineered for specific uses, power requirements, and duty cycles. Below we describe the most common types of air compressors, their working principles, and their best-fit applications.

Reciprocating (Piston) Compressors: These compressors use one or more pistons driven by a crankshaft to compress air within a cylinder. Available in single-stage (for moderate pressure needs, such as tire inflation and small air tools) and two-stage designs (for higher pressure applications like industrial equipment and auto shops), reciprocating compressors are valued for their affordability and simplicity. They tend to be louder than other types, making them better suited to garages, workshops, and construction sites.

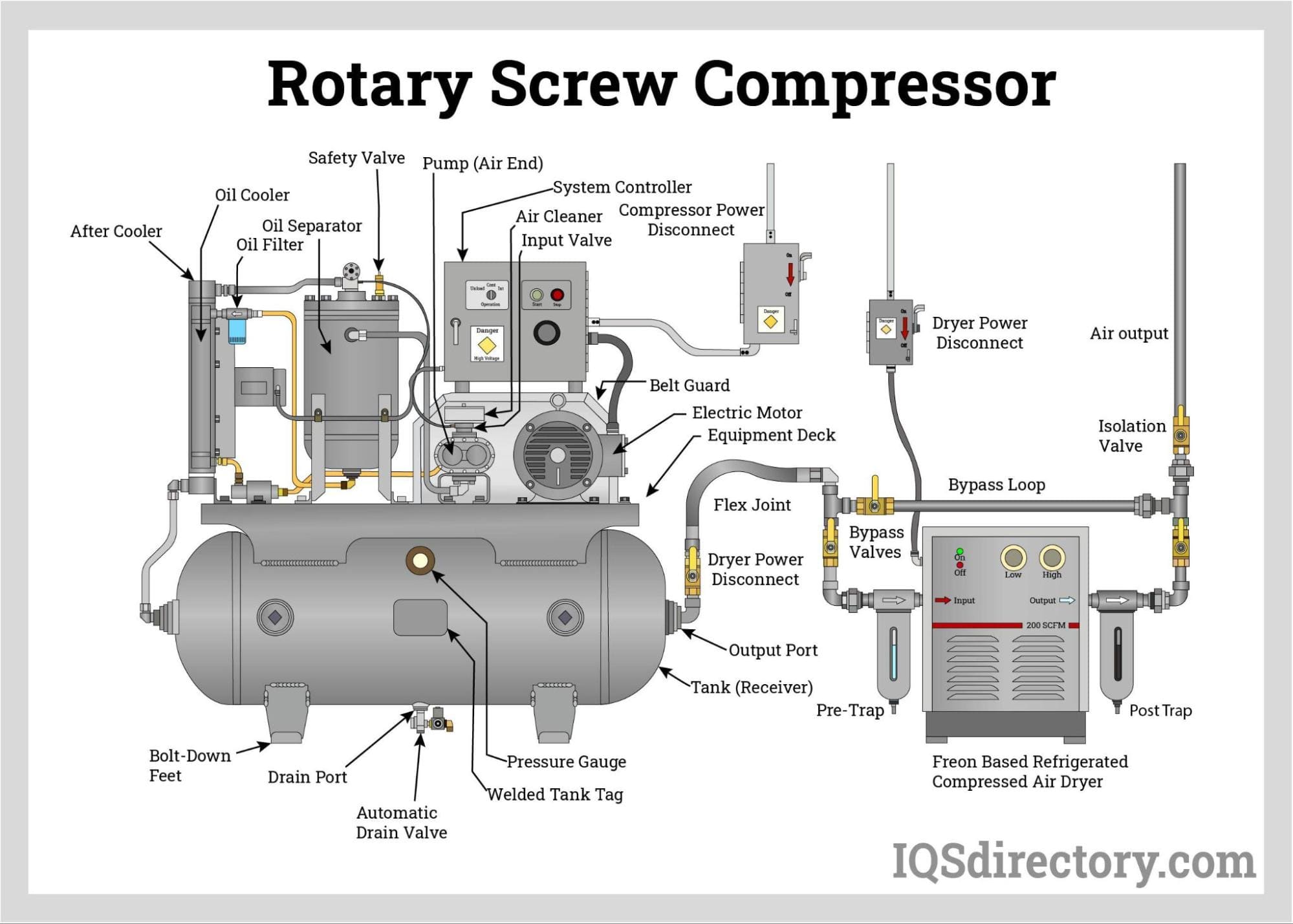

Rotary Screw Compressors: Featuring a pair of intermeshing helical screws, rotary screw compressors provide a continuous, steady supply of compressed air. Their design allows for quiet operation, higher efficiency, and suitability for demanding industrial environments that require non-stop air—such as manufacturing plants, assembly lines, and food/beverage processing facilities. These compressors are favored for their durability, energy efficiency, and long service life.

Centrifugal Compressors: Centrifugal air compressors use high-speed rotating impellers to accelerate and pressurize air. They are compact relative to their output, capable of generating very high flow rates and suitable for large-scale applications like power plants, chemical processing, and HVAC systems for skyscrapers. While more expensive upfront, they offer low maintenance and high reliability for critical operations.

Scroll Compressors: With two interleaved spiral elements—one stationary and one orbiting—scroll compressors gently compress air in a smooth, quiet, and oil-free process. Their clean operation makes them ideal for sensitive environments such as medical clinics, dental offices, and laboratories where air purity is critical.

Axial Compressors: Rarely used outside specialized fields, axial compressors utilize rows of rotating and stationary blades to progressively compress air. Their high efficiency at extremely large flow rates makes them essential in jet engines, gas turbines, and massive HVAC installations.

Oil-Free vs. Oil-Lubricated Compressors: Oil-free air compressors use self-lubricating materials and are designed for environments where air purity is vital—like electronics manufacturing, pharmaceuticals, and food processing—while oil-lubricated models are favored for heavy-duty industrial tasks due to their longevity and higher pressure capabilities.

Each type balances performance, noise, cost, and maintenance needs. Not sure which air compressor matches your requirements? Ask:

- What is the primary application—industrial, automotive, medical, or home use?

- How much air flow (CFM) and pressure (PSI) is necessary for your tools or processes?

- Is noise a concern? Do you need a portable or stationary unit?

Compare leading air compressor manufacturers to find the ideal solution for your operation.

Limitations of Air Compressors

While air compressors deliver significant advantages for a broad spectrum of industries, they are not without their challenges. Understanding air compressor limitations is essential for informed purchasing and optimal system management.

Energy Consumption and Operating Costs: Compressing air is inherently energy-intensive. Inefficient compressors or poorly maintained systems can drive up electricity costs, making energy efficiency and system monitoring crucial decision factors for buyers.

Maintenance Requirements: Regular maintenance is necessary to prevent air leaks, mechanical wear, and contamination. Scheduled maintenance—such as oil changes, filter replacements, and leak detection—keeps compressors running efficiently and extends equipment life. Lapses in maintenance can result in reduced performance, unexpected downtime, and costly repairs.

Noise and Vibration: Air compressors, particularly reciprocating models, can generate considerable noise and vibration. In noise-sensitive environments, such as offices or healthcare settings, sound-dampening enclosures, vibration isolators, or silent compressor models may be necessary.

Heat Generation and Moisture Management: Compressing air generates significant heat, which can decrease system efficiency and contribute to moisture buildup. The use of aftercoolers, air dryers, and proper ventilation is vital for maintaining safe and efficient operation.

Space and Portability Constraints: Large, industrial air compressors can occupy substantial floor space and may require permanent installation. For mobile applications, compact or portable air compressors are available, but often at the expense of storage capacity or output.

By proactively addressing these limitations—choosing energy-efficient, low-noise, and properly sized compressors, and adhering to maintenance best practices—users can maximize the value and reliability of their air systems.

Benefits of Air Compressors

Despite their limitations, air compressors are celebrated for their transformative impact across industries and applications. Investing in the right air compressor yields numerous operational, financial, and safety benefits.

Boosted Efficiency and Productivity: Air compressors power a wide array of pneumatic tools and automated machinery, enabling faster and more consistent task execution compared to manual labor. This translates to increased throughput in manufacturing, streamlined automotive repairs, and improved workflow in construction.

Cost Savings: By reducing the reliance on manual effort and extending the lifespan of tools (which operate more efficiently on consistent compressed air), air compressors help lower operational expenses. Many industries report significant cost reductions from adopting compressed air systems for routine and specialized tasks.

Unmatched Versatility: Air compressors support a diverse range of applications—from inflating tires and powering spray guns to sandblasting, pressure washing, and even food packaging. Their adaptability makes them equally valuable for hobbyists and large-scale industrial operators.

Enhanced Workplace Safety: Pneumatic tools powered by compressed air are often lighter and safer than their electric counterparts, reducing the likelihood of operator fatigue and electric shock. By automating repetitive or hazardous tasks, compressed air systems also minimize workplace injuries.

Clean and Oil-Free Air Supply: Applications such as medical, dental, electronics, and food production require contaminant-free air. Oil-free air compressors, with advanced filtration and drying, deliver the purity necessary to maintain stringent quality and safety standards.

Portable and Stationary Options: Portable air compressors are designed for mobility, making them perfect for on-site construction, roadside repairs, and remote maintenance operations. Stationary compressors, on the other hand, provide robust, high-capacity performance for continuous-use scenarios.

Quick Start-Up and Pressure Adjustment: Modern air compressors feature rapid start/stop controls and user-friendly pressure adjustment mechanisms. This enables instant access to compressed air and precise regulation for different tools and equipment requirements.

Reduced Environmental Impact: Advances in compressor technology, such as variable speed drives and energy recovery systems, help lower energy consumption and emissions—making modern air compressors an eco-conscious choice for forward-thinking businesses.

Want to know which air compressor features deliver the highest ROI for your application? Explore our detailed manufacturer listings and product guides.

Applications of Air Compressors

Air compressors are essential in a multitude of sectors, thanks to their ability to deliver reliable, high-pressure air on demand. Here are just a few of the most prominent air compressor applications across industry, commerce, and home use:

Manufacturing and Industrial Applications:

- Tool Power: Air compressors run pneumatic tools such as impact wrenches, drills, sanders, staplers, and spray guns, driving productivity in assembly, fabrication, and finishing processes.

- Automation: Pneumatic systems powered by compressed air control robotics, actuators, and conveyor belts for precise, high-speed manufacturing and material handling.

- Process Control: In chemical, pharmaceutical, and food processing plants, air compressors actuate valves, regulate mixing, and maintain clean environments.

- Energy Sector: Oil and gas drilling, pipeline testing, and hydraulic fracturing rely on high-capacity compressors for safe and efficient operations.

Construction and Heavy Equipment:

- Compressors operate jackhammers, drills, nail guns, and other essential tools at construction sites, supporting everything from foundation work to finishing touches.

- Mobile compressors offer flexibility for remote or large-scale projects, ensuring uninterrupted workflow.

Automotive and Transportation:

- Air compressors inflate tires, power impact tools, and operate paint sprayers in auto repair shops and body shops.

- Large vehicles and buses use air compressors in braking systems for enhanced safety and reliability.

Medical and Dental Settings:

- Air compressors power dental drills, cleaning tools, and air abrasion units for precise and sterile operation.

- Medical compressors deliver clean, dry, and oil-free air for ventilators, respiratory devices, and laboratory equipment.

Home, DIY, and Small Business:

- Homeowners use compact compressors for inflating sports equipment, operating airbrushes, spray painting, and powering nail guns.

- Small businesses deploy air compressors for cleaning, maintenance, and light manufacturing tasks.

Aerospace and Advanced Technology:

- Specialized compressors support aircraft system testing, wind tunnel experiments, and even spacecraft life support systems.

Looking for air compressors tailored to your industry? Browse manufacturer profiles or use our RFQ form to request custom solutions.

The Future of Air Compressors

The future of air compressors is marked by innovation, sustainability, and digital transformation. Here’s how emerging trends are shaping next-generation compressed air solutions:

Smart Technology and IoT Integration: Connected, “smart” air compressors are now equipped with sensors and wireless communication, enabling real-time monitoring, remote diagnostics, and predictive maintenance. IoT-enabled compressors help prevent downtime, optimize energy use, and provide actionable insights for operational efficiency.

Variable Speed Drives (VSD): Modern compressors increasingly use VSD technology to match motor speed to real-time air demand, significantly reducing energy waste and extending equipment life. This dynamic control is especially valuable for facilities with fluctuating air requirements.

Renewable Energy and Sustainability: The integration of solar and wind power with air compressor systems is reducing environmental impact and operating costs. Eco-friendly refrigerants, oil-free compression, and energy recovery systems are also gaining traction as industries aim to meet stricter emissions regulations.

Advanced Materials and Design: Lighter, more durable materials and innovative heat dissipation techniques are improving compressor efficiency, reducing weight, and enabling more compact, portable models without sacrificing power.

Noise and Vibration Reduction: Next-generation compressors utilize advanced noise-dampening technology, vibration isolation, and precision engineering to minimize sound—a game-changer for office buildings, medical centers, and residential settings.

Industry-Specific Solutions: As industries evolve, the demand for customized compressors grows. Aerospace, alternative energy, healthcare, and precision electronics are driving the need for specialized, ultra-clean, and energy-efficient air solutions.

Regulatory and Environmental Compliance: Upcoming global standards for energy efficiency and emissions are influencing compressor design and operation. Manufacturers are developing “green” compressors to help businesses meet their compliance targets.

Curious how these trends impact your air compressor investment? Explore our expert guides or contact a supplier for tailored advice.

Choosing the Correct Air Compressor Supplier

Selecting the right air compressor manufacturer or supplier is critical to achieving optimal performance, reliability, and value. Here’s how to make the best choice:

- Assess Supplier Expertise: Use our directory to review business profiles, evaluating each supplier’s experience, certifications, and product range. Does the supplier specialize in industrial, medical, or portable air compressors?

- Compare Product Offerings: Quickly preview available models, features, and technical specs using our patented website previewer. Consider options such as oil-free designs, variable speed drives, and integrated filtration systems tailored to your needs.

- Streamline Your Inquiries: Use our RFQ (Request for Quote) form to contact multiple suppliers at once. Clearly outline your requirements—desired flow rate (CFM), pressure (PSI), duty cycle, mobility, and any application-specific features.

- Evaluate Support and Service: Look for suppliers with robust technical support, maintenance services, and readily available spare parts. Prompt service and comprehensive warranties are key factors for minimizing downtime.

- Request References and Case Studies: Ask for client testimonials or industry case studies demonstrating the supplier’s ability to deliver reliable, cost-effective solutions.

Ready to take the next step? Browse our comprehensive directory of air compressor manufacturers and use our RFQ form to jumpstart your sourcing process. Find the perfect partner to power your next project with confidence.

—

By combining an in-depth understanding of air compressor history, components, types, benefits, applications, and future trends, this guide empowers you to make informed decisions—whether you’re a first-time buyer, facility manager, or procurement specialist. For further research, product comparisons, and purchasing support, explore our manufacturer listings or reach out for personalized recommendations.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services